LRS Starter

Introduction:

In Squirrel Cage induction motor, its rotor is a squirrel cage type, there is no external resistance circuit the bars of the rotor are completely slotted. The rotor resistance is very low so that the current in the rotor is high which makes its starting torque poor.

In Slip ring induction motor, it has rotor of wound type, external resistance is connected with a rotor which makes rotor resistance high when starting, so that the current in the rotor is low which makes its starting torque high.

Motor during starting tends to draw 6 to 8 times of full load current depends upon the Motor size and Rating, such high current results in huge voltage dip which may results in stalling of motor instead of starting. During this motor start, the other loads which are connected to this bus may have an undervoltage they may also feel consequence. In order to prevent such high inrush current, a device which limits this high starting current is called a starter.

LRS Starter (Liquid Rheostat starter or Liquid resistance starter):

There are two ways a liquid resistance starter can be used

- As a primary resistance starter where the resistance is connected in series with the stator of a standard squirrel cage motor.

- As a secondary resistance starter where the resistance is connected in series with the rotor of a wound rotor motor

Working of LRS Starter:

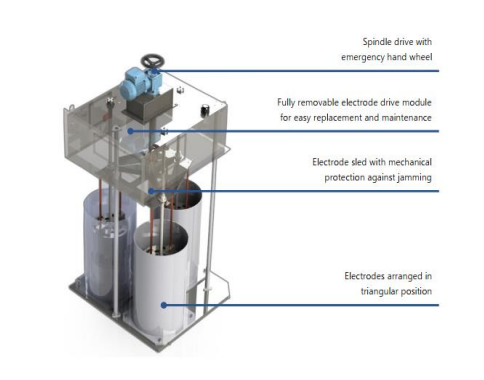

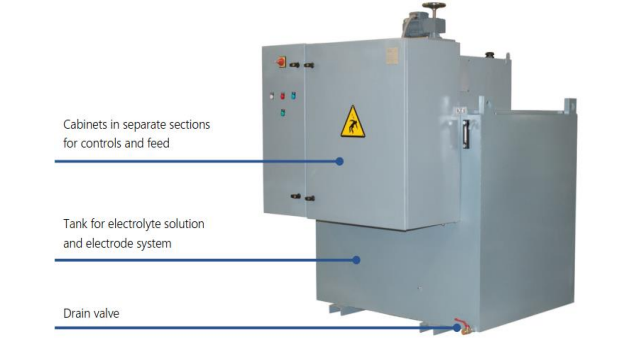

The LRS is a rectangular tank having electrolyte in it and works on the principle of resistance cutting. The electrolyte solution of Sodium Carbonate ( 𝑁𝑎2𝐶𝑜3) acts as a special liquid resistor, is connected in series to the rotor circuit of slip ring motor. Basically, the liquid resistor consists of metal electrodes in a tank of electrolyte as shown below figure. Usually, the solution used is a few percent of sodium carbonate by weight in clean water. There are two electrodes are present fixed and movable electrodes. The fixed electrodes are mounted at the bottom of the tank and adjustable electrodes will be mounted at the top of the electrolyte tank. The current flows between the electrodes through the electrolyte solution. By changing the distance between the upper and lower electrodes, the resistance is reduced smoothly. When the position of moving electrode was changed to centre of the displacement between the bottom and top of the fiberglass tank. The LRS resistance is roughly proportional to the distance between the bottoms of electrolyte tank and its top electrode. The liquid resistor gets to work when the motor starts and its resistance gradually decrease during starting, so as the motor can start smoothly and accelerate eventually at minimal rated current and maximum torque. After motor reaching its certain speed, the rotor is short circuited and it acts like a squirrel cage motor.

In addition, the fluid acts as an energy storage medium for the dissipated heat during start-up procedures. Following the start-up, the energy is then slowly dissipated to the atmosphere over the tank surface (heat exchanger for faster cooling can be supplied optionally).

Advantage of LRS:

- It works similar like a Stator resistor and rotor resistor starter but it gives smooth progressive acceleration.

- Resistance value can be easily modified, even by the user.

- Silent operation

References:

1. Elshiekh K. Mohammedsaeed, Abdelrahman A. Karrar, “Finite Element Method Based Design of a Liquid Rheostat Motor Starter” IEEE International Conference Paper, December 2016.

2. AOIP Electrolytic starter (LRS) for Slip ring motors.

No comment