Motor Acceleration Study

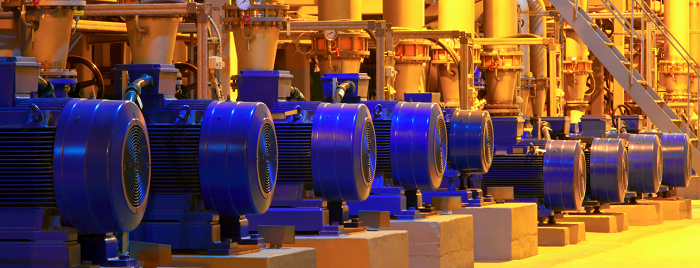

Motor acceleration study are performed on industrial and large commercial systems where large motors can have unwanted consequences on the performance of it and surrounding equipment. The starting current of most AC motors is several times (5 to 7) the normal full rated load current when starting from full line voltage. These large current requirements can result in Nuisance tripping of protection breakers, Excessive running currents, drop-in terminal voltage, triggering of under-voltage relays, Low starting torques resulting in a failure to start, stalling of other running motors connected to the power system. The impacts will be even more severe as the industry is shifting towards energy-efficient motors where the starting current high as 10 to 12 times the full load current.

Motor acceleration study are performed on industrial and large commercial systems where large motors can have unwanted consequences on the performance of it and surrounding equipment. The starting current of most AC motors is several times (5 to 7) the normal full rated load current when starting from full line voltage. These large current requirements can result in Nuisance tripping of protection breakers, Excessive running currents, drop-in terminal voltage, triggering of under-voltage relays, Low starting torques resulting in a failure to start, stalling of other running motors connected to the power system. The impacts will be even more severe as the industry is shifting towards energy-efficient motors where the starting current high as 10 to 12 times the full load current.

The ultimate objective of the motor acceleration studies is to check whether a motor can successfully start or not considering different operating conditions like starting the motor with baseload, starting the motor in the absence of grid (only generator ON condition), and ensuring the system operates within the prescribed voltage limit during the starting transients. Both the static and dynamic motor can be carried out however more detailed information like motor and load dynamic load models are required to perform the dynamic acceleration study. Ideally, a motor-starting study should be conducted before a large motor is purchased, such that the motor can be installed with confidence that the motor’s life and applications performance will be satisfactory, static acceleration is preferred at this stage due to the non-availability of detailed information.

WHY MOTOR ACCELERATION STUDY?

- To identify whether the motor can start or not under different operating scenarios with acceptable voltage.

- To study the impact of starting transients on nearby running motors.

- To accurately evaluate the motor/load speed-torque characteristics and to find acceleration time (Possible only through dynamic study).

- To check whether the transformers, power sources, motor feeders, and the corresponding protective devices are sized properly to handle the starting transients.

- To identify the need for the different types of starting devices and drives.

HOW TO PERFORM MOTOR ACCELERATION STUDY?

- Collection of inputs (SLD, Electrical datasheets of all equipment, and FAT reports (if available), MOV data, Dynamic model, inertia details of load and motor, Fault current contribution from power sources, Detailed model of exciters, governor, power factor correction devices and other voltage regulating devices)

- Modelling the system in software

- Finalizing the study case scenarios (Scenarios will consider minimum fault current contribution from the power source, the baseload connected to the system, grid voltage variations, system configuration changes, simultaneous motor starting , and other scenarios requested by the client)

- Carrying out simulation

- Submission of a detailed report

- Presentation of study findings

OUTCOMES OF MOTOR ACCELERATION STUDY

- Detailed report explaining the input data, switching events, operating scenario, observations, and recommendations

- Graphs showing torque-slip characteristics, bus voltage, motor terminal voltage, kvar, motor torque, load torque, accelerating torque, frequency (when VFD is used), V/HZ, etc.

- Presentation to easily spot out abnormal conditions like voltage limit violations, overloading of equipment, longer acceleration time, exciter limit violations motor failing to start, stalling of running motor, etc.

- Proposing applicable solutions to address the issues. (Ex: Recommendation of starters, drives and motor starting sequence)

REFERENCE STANDARDS

- IEEE 399-1997 – IEEE Recommended Practice for Industrial and Commercial Power Systems Analysis

- IEEE 3002.7 – 2018 Recommended Practice for Conducting Motor-Starting Studies and Analysis of Industrial and Commercial Power System

- IEC 60034 – Rotating Electrical Machines

- NEMA – National Electric Manufacturers Association