What Is an Arc Flash Study?

An Arc Flash study is a risk assessment of a workplace environment that determines Arc Flash hazards. It is basically a study to calculate incident thermal energy and Arc Flash boundary & recommendations for the mitigation of Arc flash hazards by using appropriate PPE.

Why Do You Need Arc Flash Studies?

To protect workers from workplace hazards. Every industrial/ commercial power system is potentially risky. Specifically, electrical shock and Arc Flash, at any time employees are handling electrical equipment while energized.

Handling Electrical equipment includes at energized condition, the operation, maintenance, testing, and troubleshooting of fully enclosed switches and power circuit breakers as well as exposure to the energized parts of the switchgear, panels, DBs and etc.

We cannot de-energize the circuit for the above activities in the case of critical process industries. The plant may suffer from various losses if we do so.

When And Where Do You Need Arc Flash Studies?

Ask yourself these questions?

- Could you guarantee that your workplace will not have an electrical accident including Arc-Flash in the future?

- Could you avoid the maintenance activities of switchgear at energized conditions by affording the various loss of offline maintenance?

- Is your system voltage level lesser than 208V?

If your answer is NO for any one of the above questions, then say absolute YES to Arc Flash Study.

An Arc Flash study must be completed before a worker is exposed to an electrical hazard. An Arc Flash risk assessment should be reviewed every five years, or any time modifications such as changes in the load or protective equipment are made to the facility that can affect the outcome of the study.

Who Can Perform Arc Flash Studies?

Arc Flash studies should be performed by experienced and qualified electrical engineers knowledgeable in power system engineering, IEEE 1584, NFPA 70E, short circuit, device coordination, and Arc Flash studies.

Reference Standards to Perform Arc Flash Study

IEEE 1584-2018: IEEE Guide for Performing Arc-Flash Hazard Calculations.

IEEE 1584.1-2022: IEEE Guide for the Specification of Scope and Deliverable Requirements for an Arc-Flash Hazard Calculation Study in Accordance with IEEE Std 1584.

NFPA 70E -2021: Standard for Electrical Safety in the Workplace.

IEEE 1584 calculations are known as an incident-energy analysis. It is defined as “the amount of thermal energy impressed on a surface, a certain distance from the source generated during an electric arc event.”

The study’s final results are used to select Arc-rated PPE and clothing with a sufficient arc rating and establish what is known as an Arc Flash boundary. The PPE category method relies on tables in NFPA 70E that assign PPE categories based on the equipment type and specific parameters.

How To Do Arc Flash Study?

First and foremost, we need to define the scope and deliverables of the study as per IEEE1584.1:2022.

Following steps to calculate the incident energy and define Arc-Flash boundaries as recommended by IEEE1584:2018.

Step 1: Collect the system and installation data

- A qualified Engineer needs to visit the plant and collect the required data to perform the Arc Flash study.

Step 2: Determine the system modes of operation

- One-line diagrams must be developed or updated to show the current configuration and modes of operation for the power system.

Step 3: Determine the bolted fault currents

- A short circuit study is required to determine the magnitude of current flowing throughout the power system at critical points at various time intervals after a “fault” occurs.

Step 4: Determine typical gap and enclosure size based on system voltages and classes of equipment

- Actual gap measurements from the installed equipment may be used if available.

- If not, we need to follow the values provided in the standard.

Step 5: Determine the equipment electrode configuration

- Need to collect the data as available on the site.

- For example, a panel board may contain both VCB and VCBB electrode configurations. switchgear may have HCB depending on the bus and conductor arrangement.

Step 6: Determine the working distances

- Arc-Flash protection is typically based on the incident energy level on the person’s head and torso at the working distance and not the incident energy on the hands or arms.

- Typical working distances can be found in IEEE 1584:2018 based on the class of equipment.

Step 7: Calculation of arcing current

- The total arcing current at a given location is calculated based on the total bolted fault current available at that location.

- The calculated arcing current is lower than the bolted fault current due to arc impedance.

Step 8: Determine the arc duration

- The arc duration is defined as the time it takes the upstream energizing source of arcing current to stop providing current or energy to the arc fault.

- Typically, the clearing time of overcurrent protective devices depends on the magnitude and/or direction of the arc current passing through their current sensing equipment (current transformers, relays, etc.).

Step 9: Calculate the incident energy

- Incident energy calculations should be performed at each of the switchgear, panels, and DBsthat are defined to determine the highest magnitude incident energy or “worst-case” condition.

Step 10: Determine the Arc-Flash boundary for all equipment.

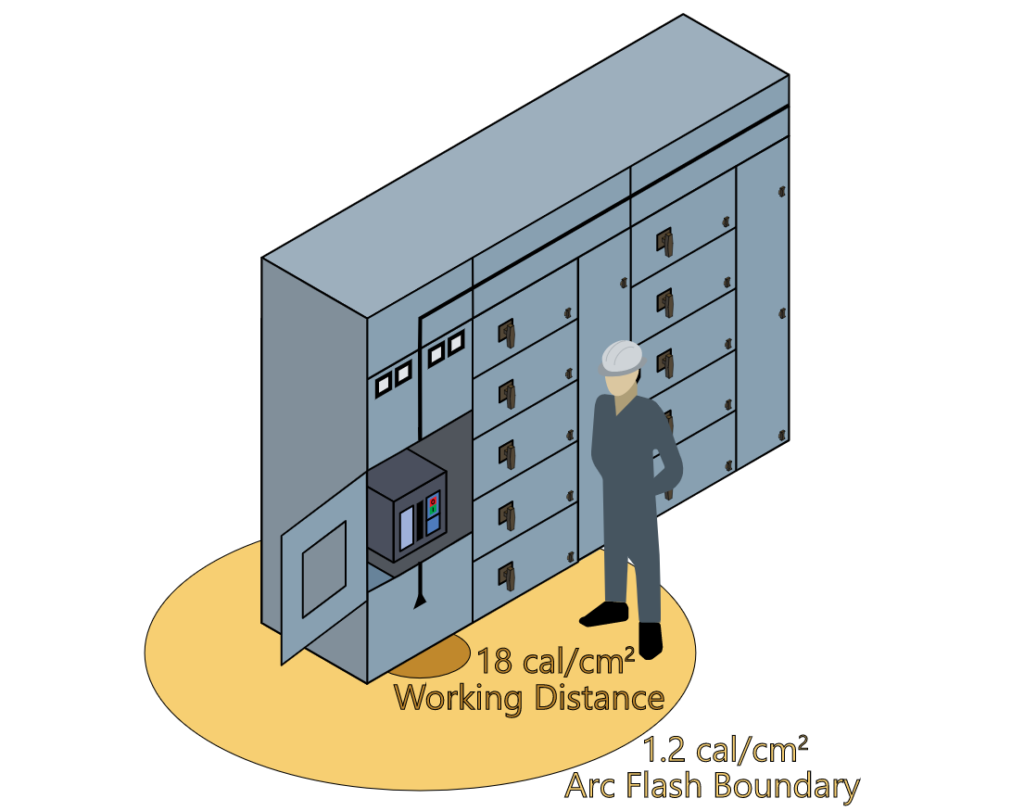

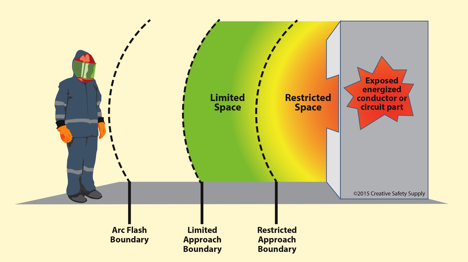

- The Arc-Flash boundary is the distance from a prospective Arc Flash where the incident energy is 5.0 J/cm2 (1.2 cal/cm2).

WHAT’S NEXT!?

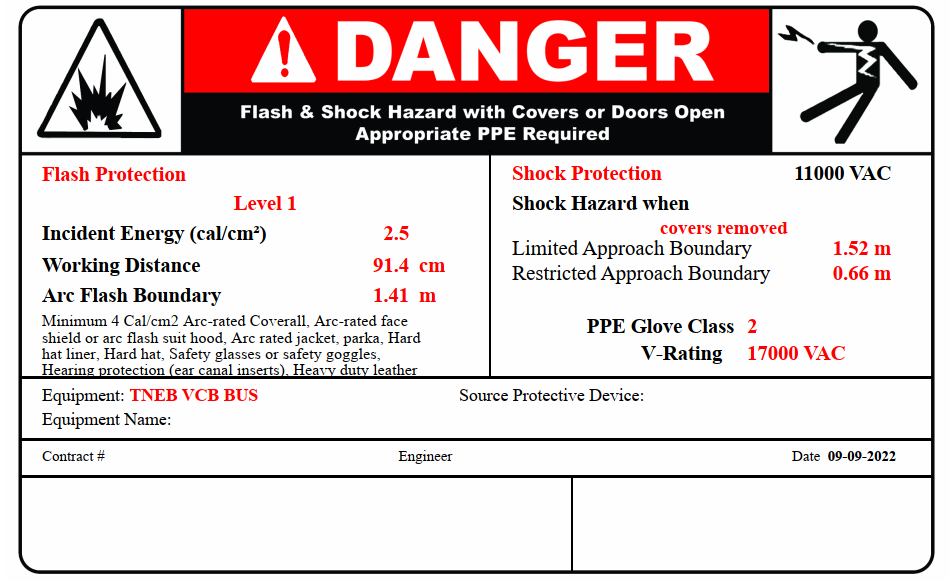

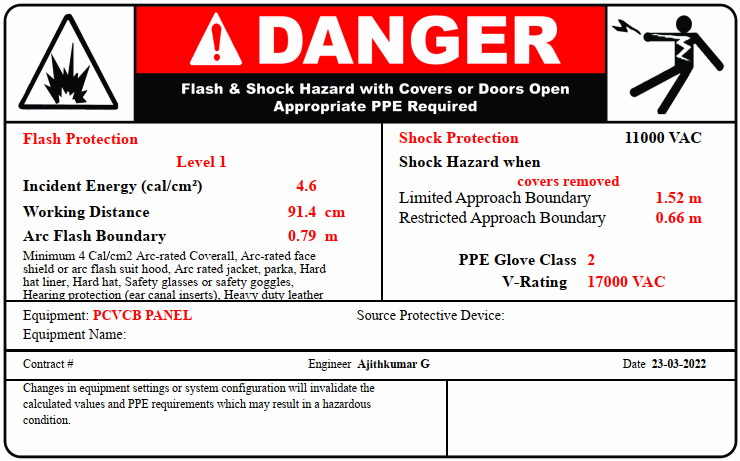

After calculating the incident energy, the Arc flash boundaries for all the equipment. The study’s final results are used to select Arc-rated PPE and clothing with a sufficient arc rating and establish an Arc Flash boundary.

And it is recommended to paste the Arc Flash labels on the front side of every panel to create awareness among the workers.

It is advisable to mark Arc Flash boundary and limited approach boundary in front of every panel as per IEEE1584 & NFPA 70E 2021 recommendations.

Arc Flash Labels

And it is recommended to paste the Arc Flash labels on the front side of every panel to create awareness among the workers.

The labels have the details of Incident energy level, Working distance, Limited approach boundary, Restricted approach boundary, Arc Flash boundary, and recommended Arc Rated PPE.

Arc Flash Mitigation Hierarchy Triangle

This triangle shows the best technics to get rid of Arc Flash hazards.

No comment