PROJECT DETAILS

The Schaeffler Group, a major family-owned company globally, focuses on products. Their Hosur manufacturing site produces LuK-branded clutch systems and dual mass flywheels for various vehicles. In India, Schaeffler has engineering and research teams that support product development. Demonstrating a commitment to employee safety, they initiated an Arc Flash study to assess and address electrical safety hazards at their workplace. Schaeffler awarded Power Projects the contract to conduct the Arc Flash Study for their Hosur plant

The Schaeffler Group, a major family-owned company globally, focuses on products. Their Hosur manufacturing site produces LuK-branded clutch systems and dual mass flywheels for various vehicles. In India, Schaeffler has engineering and research teams that support product development. Demonstrating a commitment to employee safety, they initiated an Arc Flash study to assess and address electrical safety hazards at their workplace. Schaeffler awarded Power Projects the contract to conduct the Arc Flash Study for their Hosur plant

Scope

The scope of the work is to conduct an arc flash study for the power system network at Schaeffler India Limited.

It involves estimating the following:

- Incident Energy

- Arc Flash Boundary PPE Level

Steps involved in arc flash study

- Site visit for data collection and verification of exiting plant power system.

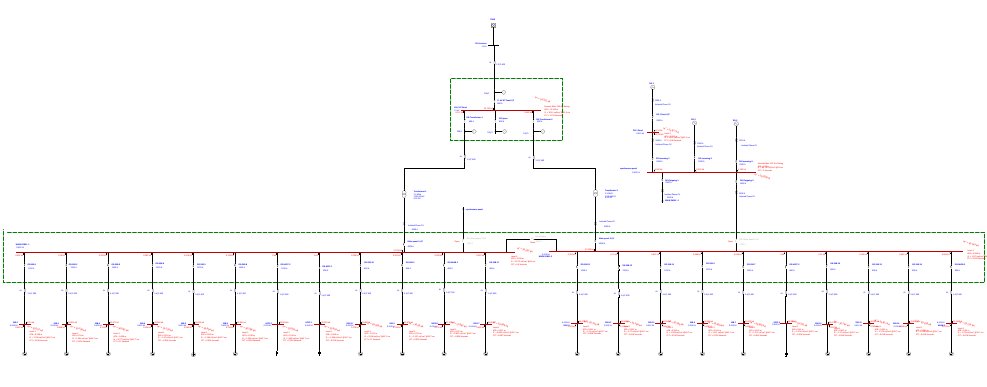

- Electric system modelling on ETAP (Electrical Transient Analyzer Program) Softwere for conducting.

The following steps are,

- Short Circuit Study

- Protective Device (Relay & Release) Co-ordination

- Arc Flash Study

Plant electrical system Description

- Plant avails 11 kV power from utility and further, plant has 1 nos. of 11/0.433 kV distribution transformers.

- The maximum Grid power import demand is2.5MVA.

- Plant contains PCC panels 22nos, switchgear panels 5nos.

- Emergency DG sets 3nos at 415V used to provide back up to the critical/ emergency load of the plant in case of unavailability of grid Power.

- In case of a grid failure, the system is supplied by 3MW DG sets

Standard IEEE-1584-2018

IEEE 1584-2018 is a standard that outlines methods to calculate the potential arc flash hazard in electrical systems. It provides guidelines for predicting arc flash incident energy, which is crucial for assessing the risks to personnel working on or near energized equipment. This standard takes into account various factors like system voltage, fault current, and equipment configuration to estimate the energy released during an arc flash event. By using empirical formulas derived from extensive testing.

IEEE 1584-2018 helps in determining appropriate safety measures, such as personal protective equipment (PPE) requirements and safe working distances, to mitigate the risks associated with arc flashes in electrical installations. Compliance with this standard is vital to ensuring the safety of workers and preventing severe injuries due to electrical accidents.

Standard NFPA-70E 2021

NFPA-70E, created by the National Fire Protection Association, serves as a comprehensive standard ensuring workplace safety concerning electrical hazards, particularly focusing on the potential dangers of arc flash incidents. This standard provides detailed guidelines and protocols for conducting hazard analyses, determining appropriate personal protective equipment (PPE), and implementing safe work practices to mitigate the risks associated with electrical work and minimize the impact of arc flashes, thereby safeguarding the well-being of workers.

- The Analysis for the Power System Study for Schaeffler India limited are performed using ETAP version 20.5

- ETAP stands for Electrical Transient and Analysis Program. It is a powerful software tool used for the design, analysis, and operation of electrical power systems.

- ETAP is primarily used by engineers and professionals in the field of electrical engineering to model and simulate electrical networks, perform load flow analysis, short circuit calculations, transient stability studies, and more.

STANDARDS FOLLOWED

- IEEE 1584-2018 IEEE Guide for Performing Arc-Flash Hazard Calculations.

- IEEE 1584.1-2022 IEEE Guide for the Specification of Scope and Deliverable Requirements for an Arc-Flash Hazard Calculation Study by IEEE Std 1584.

- NFPA 70E-2021 Standard for Electrical Safety in the Workplace

- IEC 60076-5 2006 Power transformers – Part 5: Ability to withstand short circuit

Design Engineering of Arc Flash Mitigation System

- Preparation of scheme drawings

- Preparation of BOM and Technical Specifications

- Design and supply of arc flash awareness labels

- Preparation of Technical pre-requisites, site

- Requirements as well as, detail SOP for carrying out

- scheme implementation at site

DATA COLLECTION FROM SITE

ETAP Simulation result for arc flash study

Challenges faced

In this project, we encountered challenges when obtaining data from LV panels due to their live nature. During the modeling phase, issues arose with MV panels and generator panels, as they exhibited the highest incident energy due to prolonged fault clearing times. As a suggestion, we advised against conducting live maintenance. Additionally, we omitted arc flash labels for specific panels. However, for the remaining panels, we implemented arc flash labels with varied PPE categories, determined by the incident energy levels.

The plant considered for the arc flash simulation is with 11kV grid supplying the loads. Diesel generator operation during grid outage is evaluated. To ensure comprehensive safety assessments, we have conducted multiple arc flash analysis cases to identify the most critical scenarios.

We have observed that certain switchgear exhibited fault clearing times of 1.145 and 2 seconds. Since we are unable to determine the incident energy to overcome.

Arc Flash Mitigation techniques

Mitigating arc flash risks involves steps like assessing hazards, using protective devices, upgrading equipment, implementing safety protocols, providing proper training, and using personal protective equipment (PPE). This process includes analyzing potential hazards, upgrading systems for better safety, setting up safety protocols and training, and ensuring workers have and use appropriate protective gear.

Visited the plant facility to get complete clarity about the existing installations in detail and design the Arc Flash Mitigation System accordingly without having the panel drawings

During Implementation of project

The engineers’ team worked during the Diwali holidays, which was the only available shutdown period for our team to execute the Arc Flash study Implementation job.

The expert team of engineers completed the entire execution job without any time delays.

They delivered the project report on time, without any mistakes, and with good quality.

STUDY OBSERVATIONS AND RECOMMENDATIONS

- Based on the arc flash study results, it is advisable to wear proper PPE 0.415kV level as per NFPA 70E 2021 recommendations.

- We have advised to mark arc flash boundary, limited approach boundaries, and restricted approach boundary lines in front of the panels as per the given results.

- We have provided arc flash labels as deliverables and advised them to place danger labels on respective switchgear.

No comment