Earthing Study

Earthing study is critical for the safety, reliability, and performance of electrical systems. Properly designed and analyzed earthing systems reduce risks like electrical shock, equipment damage, and system instability. At Power Projects, we offer comprehensive earthing studies for power systems, industrial plants, renewable energy facilities, and substations. Utilizing advanced software tools like ETAP and CDEGS, we ensure your system meets international standards and operates optimally under all conditions.

Latest Projects Making an Impact

- Dubin Gas Power Plant

- Amazon Web Service Data Center

- Colt Data Center

- Port of Tyne

- Roxboro E-Mobility Substation

In-Depth Analytical Services

Our earthing study include the following detailed analyses:

- Soil Resistivity Analysis:

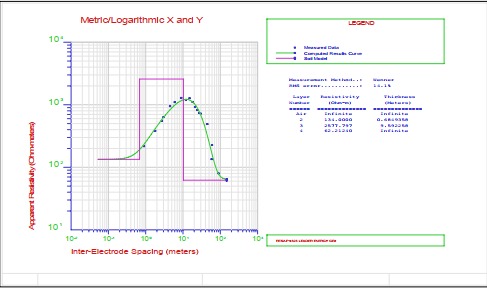

- Measures and analyzes soil properties for optimal grounding configurations.

- Ground Grid Design and Optimization:

- Designs efficient grounding grids for substations, industrial facilities, and renewable energy plants.

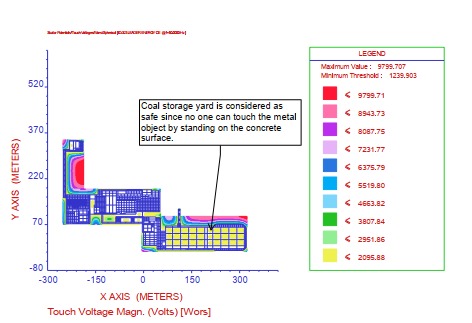

- Step and Touch Voltage Analysis:

- Assesses safety levels during fault conditions using ETAP and CDEGS.

- Fault Current Distribution Analysis:

- Evaluates the flow of fault current through grounding systems.

- Lightning Protection System Design:

- Designs and verifies protection systems to safeguard against lightning strikes.

- Compliance Audits and Safety Assessments:

- Verifies adherence to standards like IEEE 80, IS 3043, and IEC 60364.

Adhering to Global and Regional Standards

Our Earthing study comply with key global and regional standards, including:

- Global Standards:

- IEEE 80: Safety in AC Substation Grounding.

- IEEE 837: Permanent Connections in Substation Grounding.

- IEC 60364: Earthing of Electrical Installations.

- BS 7430: Code of Practice for Protective Earthing.

- Regional Standards:

- India: IS 3043, CEA Guidelines.

- Saudi Arabia: SEC Grounding Specifications.

- Europe: EN Grounding Standards.

- United States: IEEE and NFPA Standards.

- Australia: Australian Energy Market Operator (AEMO) Grounding Codes.

Advanced Tools for Accurate Earthing Study

We utilize advanced tools for comprehensive earthing study:

- ETAP:

For grounding grid design, fault current analysis, and safety compliance evaluations. - CDEGS (Current Distribution, Electromagnetic Fields, Grounding, and Soil Structure Analysis):

For soil resistivity analysis, step and touch voltage calculations, and grounding optimization.

The Value of an Earthing Study

- Safety Assurance: Safeguard personnel and equipment from electrical hazards.

- Regulatory Compliance: Ensure your system adheres to relevant standards and regulations.

- Enhanced Performance: Optimize the efficiency of grounding systems.

- Risk Reduction: Minimize operational disruptions and equipment failures.

- Cost Efficiency: Implement cost-effective grounding solutions.

- Future-Ready Systems: Prepare your system for future expansions and evolving standards.

Case Study: Grounding System Optimization for CEL I & CEL II Coal-Fired Plants, Cambodia

Problem Statement

Enhancing Grounding System Performance and Safety for 2 × 60 MW and 150 MW coal-fired plants, ensuring compliance with IEEE 80 standards.

The project aimed to evaluate and optimize the grounding systems of CEL I and CEL II plants. The focus was on maintaining personnel safety, effective fault current dissipation, and minimizing touch and step voltage risks.

Project Overview

Power Projects conducted a comprehensive grounding study for CEL I and CEL II coal-fired plants located in Preah Sihanouk Province, Cambodia. The scope involved assessing and improving the grounding system performance while addressing lightning-related protection issues.

- CEL I: 2 × 60 MW generators connected via 72 MVA transformers to 230 kV.

- CEL II: 150 MW generator connected via a 186 MVA transformer to 230 kV.

- Both plants connect to the Steung Hav 230 kV substation via a 1.9 km transmission line.

The study used CDEGS software for modeling and analysis to ensure compliance with IEEE 80 safety standards.

Challenges Identified

- Grounding Resistance

- Ensure the overall grounding grid resistance remains below 1 ohm for safe fault current dissipation.

- Touch and Step Voltage Compliance

- Maintain safe voltage levels to protect personnel during single-line-to-ground fault scenarios.

- Lightning Protection

- Address lightning strikes that caused differential protection malfunctions and equipment failures.

Scope of Work

- Analyze the adequacy of grounding conductor size for fault current conditions.

- Evaluate earthing grid resistance and ensure compliance with IEEE 80 thresholds.

- Perform touch and step voltage calculations to assess personnel safety.

- Model and analyze the grounding system using CDEGS software.

Key Findings

- Grounding Resistance:

- CEL I: 0.50 ohms.

- CEL II: 0.5049 ohms.

- Both values met the permissible limit of 1 ohm, ensuring effective fault current dissipation.

- Touch and Step Voltage:

- CEL I & CEL II complied with safety thresholds:

- Safe touch voltage: 1289.6 V.

- Safe step voltage: 4290.8 V.

- CEL I & CEL II complied with safety thresholds:

- Lightning Protection:

- Lightning-related faults were mitigated through improved grounding and optimized arrester placements.

- Conductor Sizing:

- Copper conductors of 150 mm² were adequate to withstand fault currents of up to 32 kA with a clearing time of 1 second.

- Ground Potential Rise (GPR):

- CEL I: 11,152.91 V.

- CEL II: 11,194.97 V.

- GPR values were within the acceptable range for safe operation.

Recommendations

- System Maintenance:

- Regular inspections and maintenance of the grounding system to ensure continued compliance and reliability.

- Real-Time Monitoring:

- Implement monitoring systems to detect potential grounding system faults and deviations in real-time.

- Enhanced Lightning Protection:

- Improve transmission line ground wire and arrester configurations to further mitigate lightning-induced faults.

Conclusion

The grounding systems for CEL I and CEL II met all safety and operational standards, ensuring reliable fault current dissipation and personnel protection. The study validated the adequacy of existing systems while recommending periodic reviews and real-time monitoring to sustain performance over time.

Prestigious Customers